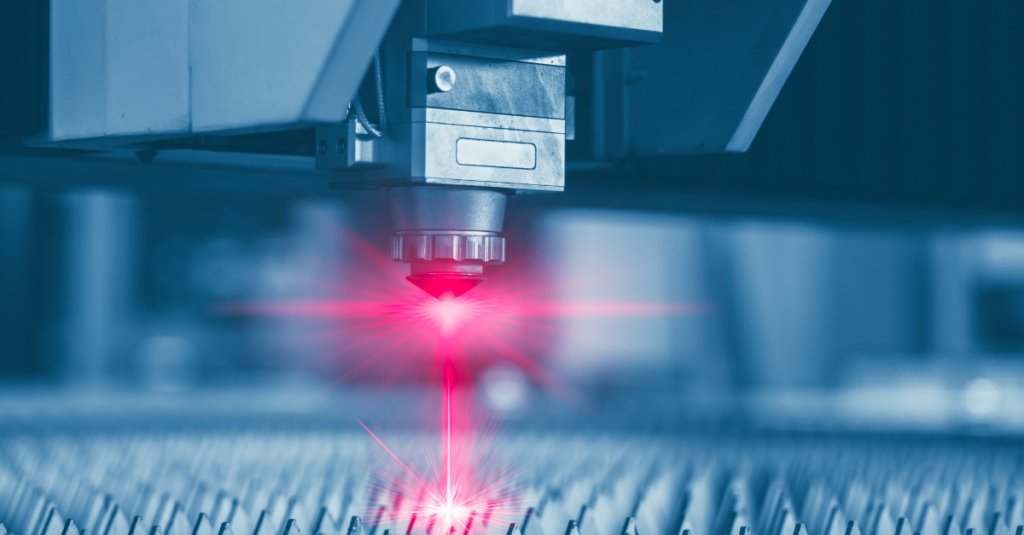

Comparing two laser systems for LIBS measurements

In a previous blog post “The Source of Light”, the working principle of a laser was described. The laser systems which will be used in the ReSoURCE Project were also mentioned, and today is the perfect opportunity to write about the differences between the two systems and the challenges faced.

The ReSoURCE laser systems, which will be used in Demonstrator A and B for LIBS measurements, emit pulses having of width of only a few nanoseconds. For the first system, 100 pulses per second (100Hz) and for the second 400 pulses per second (400Hz) are emitted. One could think that the only difference is the parameter of the repetition rate, and one would be (partially) correct. However, the increased repetition rate causes one main challenge: an increase of the thermal lensing within the laser medium.

As you can imagine no system has a 100% conversion efficiency. In the case of a laser, electrical energy is used to pump multiple diodes; these emit light at a wavelength of approximately 808nm. This specific wavelength is absorbed by the laser medium and excites electrons to a higher energy level. When falling back down to lower energy levels laser light is emitted. During the pumping process a lot of the energy is actually lost in the form of heat.

To avoid the laser medium being too warm, water flows around it to cool it down. Of course, since the water only flows on the outside of the laser medium, the heat is not evenly distributed: a temperature gradient is formed within the laser medium. The properties of the material cause a change in refractive index based on the temperature it has. The temperature gradient leads therefore to a gradient in the refractive index: it can be assimilated to being equivalent to a lens, hence the name “thermal lens”.

Lenses are present in many devices used daily: telescope, glasses, cameras and many more. These cause the object observed to either be bigger/smaller or more in focus. The same happens to the pulsed laser beam when it goes through the laser medium having a thermal lens: it gets smaller. By having a repetition rate of 400Hz instead of 100Hz, the temperature gradient is a lot wider within the laser system at 400Hz and therefore the thermal lens is also more present. To compensate, additional lenses needed to be used to avoid the pulsed beam being focused within the system, this was done successfully with promising results for later steps of the project.

Finally, the deliverable concerning the two laser sources was successfully submitted. The next step is to perform test trials using the laser systems at the LSA GmbH facility in Aachen. We will keep you posted with further updates!

Authors’ Portrait

Dorian-David Percheron

Dorian-David Percheron is a Development Engineer at InnoLas Laser GmbH, focused on the production of client-specific DPSS laser systems. He studied at the Technical University of Munich (TUM) and has a M.Sc. “Applied and Engineering Physics”. His research interests are Optics and Renewable Energies.

Paul Denck

Paul Denck is a part-time Development Engineer at Innolas Laser GmbHwho is interested in the field of electronics.

Partner