Aachen, August 30, 2023

Recycling of refractory materials avoids 800,000 tons of CO2

In the European research project ReSoURCE, experts from nine different companies and institutes are working together to develop sustainable solutions for the recycling of refractory materials. The German project partners are primarily providing laser know-how.

Refractory materials withstand high temperatures beyond 1,500 °C. They are indispensable for industrial furnaces that produce glass or ceramics, non-ferrous metals and steels, for example. The service life for refractory products ranges from a few days to many years – depending on the materials, the temperature in the melting vessel and other operating parameters. As a result, about 32 million tons of used refractory materials are produced worldwide every year, of which only a fraction is recycled.

The production of refractory materials from primary raw materials causes considerable amounts of CO2, mainly because carbon dioxide has to be removed from carbonate-type raw materials. In addition, the raw materials are largely imported into Europe. This also includes critical raw materials with risky supply chains. These alone are enough reason to reprocess used refractory materials and feed them into a circular economy, as there are currently no significant alternatives to them.

Automatic sorting system using laser technology

“Refractory products are precisely adapted to the customers’ requirements,” explains ReSoURCE project coordinator Alexander Leitner from RHI Magnesita. The optimal composition of the high-temperature resistant materials depends on the intended application, the manufacturing processes, and the related chemical properties of the process media. “This means that our products have very different compositions. Before recycling, we therefore have to separate them as precisely as possible,” Leitner continues.

The project therefore centers on an automatic sorting system for spent refractory materials. A laser unit will be used to identify the constituents of the used material on a conveyor belt without contacting them. The laser technology comes from the medium-sized company Laser Analytical Systems & Automation GmbH (LSA) from Aachen, a spin-off of the Fraunhofer Institute for Laser Technology ILT. Fraunhofer ILT is a pioneer in developing novel applications for laser spectroscopy, including sorting into pure materials for recycling with laser-induced breakdown spectroscopy (LIBS).

“At Fraunhofer ILT, we have already developed an inline measurement technique that performs a direct analysis of metal scrap on a conveyor belt and detects the composition of each piece of scrap,” explains Dr. Cord Fricke-Begemann, Head of the Materials Analysis Group at Fraunhofer ILT. “With this multi-element analysis, we can detect a large number of alloys. We are now transferring the findings to refractory materials.”

Data analysis with artificial intelligence

LSA specializes in the development and production of real-time laser analysis systems for industrial applications. The systems use pulsed laser radiation to obtain chemical information in fractions of a second without contact over distances of up to one meter. “Our laser analysis systems are used directly on the processing lines: In other words, we bring the measurement technology to the product, not the product to the laboratory. Using a flash of light, we measure the chemical composition of the moving product. Our speed is the speed of light,” says LSA’s managing director, Dr. Joachim Makowe.

In the joint project, the company InnoLas Laser GmbH from Krailling in Germany is developing the laser beam source, which emits special pulse groups to quickly penetrate non-representative surface layers on the used refractory bricks. Only then is it possible to analyze the underlying material. “The laser source for the ReSoURCE project is being developed specifically for LIBS. We are working in close cooperation with LSA and Fraunhofer ILT on questions and challenges that have arisen,” explains Dorian-David Percheron from Innolas Laser.

LSA integrates optical measurement technology with material handling to create an overall system suitable for industrial use. Fraunhofer ILT evaluates the data from the LIBS system. For this purpose, the measured spectra with the chemical information are combined with further optical sensor data and analyzed with the help of artificial intelligence. In this way, the system determines the exact composition of the refractory products and sorts the individual used refractory bricks into different material classes.

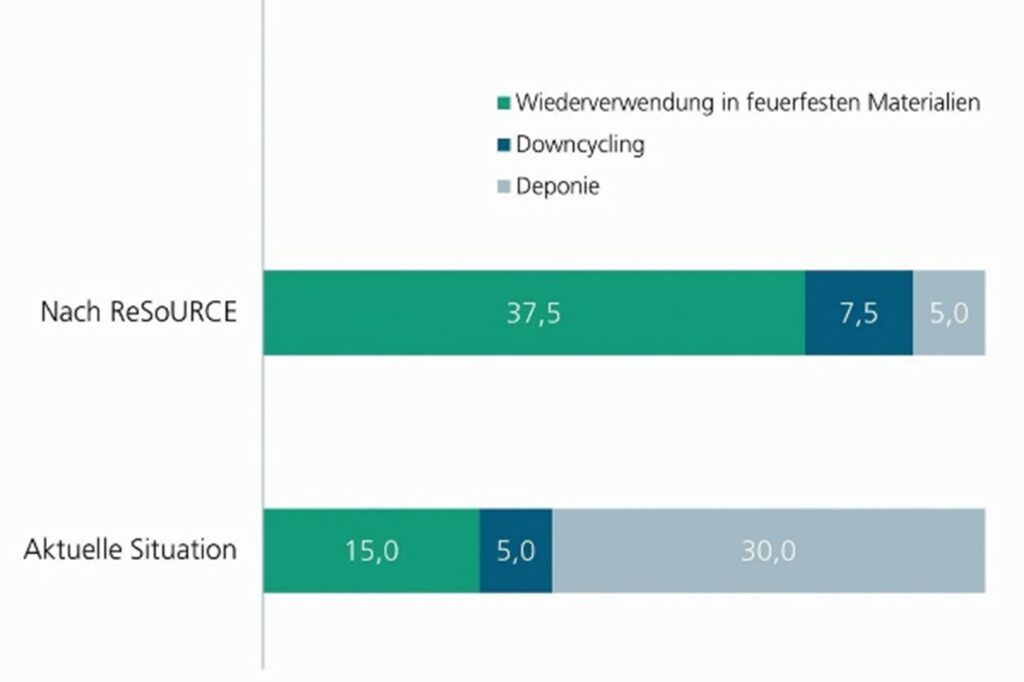

The research partners expect they can increase the industry’s potential recycling share from the previous 7 to 30 percent up to 90 percent as a result of the project findings. “We are combining the latest analysis technology with state-of-the-art software to solve a current societal problem. We can probably reduce European CO2 emissions by up to 800,000 tons per year,” says Cord Fricke-Begemann. “This is a wonderful example of how technology and innovation and a collaborative project can help in the fight against climate change.”

To gain greater insight into the project, the public can follow the research up close on a science blog on the project’s website: https://www.project-resource.eu.

Background Information

The ReSoURCE project goal is the development of a working sensor-based system for refractory waste sorting and powder handling. If the project is successful, it will enable the robust engineering of an automated sorting equipment that will increase the recycling of refractory breakout material from the current estimate of 7–30 percent worldwide (plus 10 percent of downcycling) to a total 90 percent. With approximately 32 million tons of used refractories generated annually, the ecological and societal benefits will be considerable.

The project is funded by the European Health and Digital Executive Agency (HaDEA) in the Horizon Europe Framework program (HORIZON) under the grant agreement number 101058310. The total budget is 8.5 million euros. Six million euros are funded by the EU, one million by the UK. The project’s duration is from June 2022 to November 2025 (42 months). The consortium consists of nine members (four academia and five industry). Partners come from Austria, England, Germany, Ireland and Norway. The project is led by RHI Magnesita. Other partners involved in the project are LSA GmbH (GER), Fraunhofer institute (GER), SINTEF (NOR), Montanuniversität Leoben (AT), Innolas Laser GmbH (GER), NEO (NOR), CPI (UK), and Crowdhelix (IRE).

Press Contact

Saranya Azhaarudeen,

ReSoURCE project coordinator

RHI Magnesita, Kranichberggasse 6, 1120 Vienna, Austria

E-Mail: project-resource@rhimagnesita.com