Crowdhelix is an open innovation platform that forges links between an international network of excellent researchers and innovative companies, enabling them to plan, deliver, and exploit pioneering collaborative projects and value chains. As Europe’s leading impact acceleration partner, Crowdhelix offers a unique networking, clustering and value chain creation platform managed by Impact management experts from across Europe and beyond.

The platform employs an interactive approach called the “Helix Impact Model,” which facilitates the dissemination, exploitation, and communication within EU-funded research projects. Each Helix is designed to bring together experts, RTOs, SMEs, policy makers, and other relevant actors for collaboration and impact in research and innovation. Helix communities enhance collaboration among different stakeholders along the value chain of the most pressing topics and technologies, allowing adaptation to various scientific and innovative fields, and boosting different ecosystems in the open innovation landscape.

The Helixes are a crucial component of Crowdhelix’s three-step Impact Acceleration Approach, which includes stakeholder analysis, matchmaking and clustering, profiling and connecting innovation to global end-users. This is achieved by using a machine learning driven ‘recommender engine,’ to match collaborative partnerships. Crowdhelix currently hosts 54 active Helixes where users can profile themselves, their teams, their organisations, and post opportunities to collaborate. An intelligent recommender system then matches these opportunities with the most suitable prospective collaborators, using natural language processing and machine-learning.

Any researcher, student or expert of an organisation that is already a member of the Crowdhelix Network and has a valid email domain provided by their organisation can register, post about collaborating, or connect with other organisations searching for expertise in different areas of research. Users can proactively post and respond to collaboration opportunities within the Helixes, and target specific Horizon Europe funding calls drawn directly from the EU’s database. In that sense, Crowdhelix makes it easy for diverse businesses, universities, and research organisations to find common ground, and forge strong partnerships so they can develop competitive project concepts and proposals targeting Horizon Europe funding.

The platform’s emphasis on impact and sustainability has led to the development of groundbreaking technologies and solutions across various sectors. Crowdhelix has facilitated numerous successful projects, bringing together top-tier researchers and industry leaders to tackle complex challenges.

Being a global collaboration platform for researchers and innovators, Crowdhelix’s members have collectively been awarded over €11.79 billion of funding under the EU Horizon programmes, to deliver 22,246+ pioneering projects. Learn more about successes that Crowdhelix has been able to facilitate on their outcomes page as linked here.

In addition, Crowdhelix delivers over 40 sector leading live and virtual events per year. Attending Crowdhelix events allows researchers, experts and students to focus on research and innovation domains and discover new opportunities and partnerships, as well as enabling connections with other expert members of Crowdhelix. Looking to the future, Crowdhelix plans to broaden its network and improve its services to support even more ambitious and impactful projects. The platform is set to be a pivotal player in the continuous evolution of the European research and innovation ecosystem, driving progress and delivering value to all stakeholders involved.

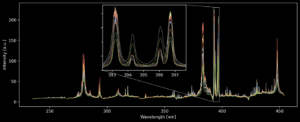

We have already highlighted the basic principle of LIBS in our previous blog article. To analyse the plasma, we split up its radiation into thousands of different wavelengths and measure them at the same time. This super-fine spectral resolution enables identification of ‘line emissions’ – sharp peaks in the spectrum caused by various chemical elements in the plasma. You can see several spectra with such peaks in the figure below. The non-linear interactions between the different elements can make the interpretation of spectra difficult. This is where artificial intelligence (AI) and here more specifically machine learning (ML) can help us in classifying the spectra into different groups of materials.

Figure 1: Several raw LIBS spectra, each line colour representing a different refractory material. The zoomed-in section shows four peaks with the two central peaks indicating aluminium, the outer two peaks indicating calcium. The different ratios of areas under each peak allow the identification of the material.

Collecting lots of data is straightforward but analysing it in real-time can quickly become challenging. The most basic approach is to input the entire spectrum with its thousands of channels into a ML model. The computer would then calculate patterns and correlations in the data which are related with the material class on a purely statistical basis. However, this will likely result in a very big and complex model with long computation time. To train the model you’d need lots and lots of data for the model to have a chance of identifying the important features.

A smarter way is to do a feature selection beforehand, so you pass only the information-rich features on to your model. One common way is doing a principal component analysis (PCA), which essentially projects the spectral data onto just a few channels while retaining as much variance of the data as possible. However, the inherent noise within the spectra, which is always present but not related to the material, spoils this approach. Instead, what is usually done with LIBS spectral data is integrating the energy within certain spectral bands, so called regions-of-interest (ROI). This method effectively averages out most of the noise. While there are some AI-based approaches to select these ROI automatically, in most cases a manual selection still wins. Here a PCA can refine this manual selection by reducing it to a few features with low collinearity, which is advantageous for ML.

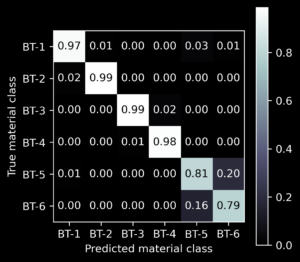

Now on to the choice of a ML architecture which will allow us to identify the material of a sample. This is usually highly dependent on the task and data on hand. As ML is still a relatively new field in science, choosing the right architecture can be more of an art than science, which requires experience and some good guesses. One constant challenge is finding the best balance between your model learning the fine details of the data, while not faultily learning the random noise as well. You do this by dividing up your data into a training set and a test set. The training set you use to adjust the model parameters, so it classifies the training data as best as possible. You do this multiple times while testing different architectures. Finally, you evaluate which model performs best with the still unused test set, therefore testing how well your model can predict from yet unseen data. A result of such a test is shown in the figure below.

Figure 2: Classifier performance when predicting the class from 3 different, yet unseen, measurements. The table shows, by the value in the upper left cell, that 97 % of the measurements predicted as class BT-1 were really originating from material BT-1, whereas 2 % were originating from material BT-2 (cell below). This model was already very good at classifying the classes BT-1 to BT-4, but there are still difficulties to distinguish BT-5 and BT-6. Therefore, the architecture and training of the model is adapted for further improvement.

This ML-based approach has another advantage over traditional solutions. While calculating the ROI values gets rid of most of the noise, there is still a significant amount present. To mitigate this, it’s possible to average over multiple measurements of the same sample. Of course, this comes with the cost of a slower measurement rate. The ML-based approach offers a better generalisation, meaning it more effectively ignores noise. This allows prediction from a single measurement already, or through combinatorial statistics, a very reliable prediction from multiple measurements.

Authors’ Portrait

Yannick Conin

Yannick Conin is a research associate at the Fraunhofer Institute for Laser Technology ILT. He graduated from RWTH University with a master’s degree in mechanical engineering, where he wrote his thesis on sensor fusion for the ReSoURCE project. His research interests include data science, metrology, optics and materials science.

“Circular economy”, “Green deal”, “Critical raw materials act” – keywords you hear all over the place. But what does it really mean? What does it imply for industries and for us as citizens? How can we accelerate important steps towards necessary transitions? Or what is hindering us?

Well, to get some answers, over the last weeks I was very enthusiastic to participate in several conferences exchanging on the latest technological developments as well as on legal and sometimes even philosophical aspects on how to increase our recycling efforts on a national and European Union level. It was a pleasure to present our contribution as RHI Magnesita and of all our partners within the project ReSoURCE to several hundreds of interested stakeholders.

Starting with the AWT2024 in Vienna, my colleague Alex and I were invited to give a talk in front of over 500 participants. Although this was very exciting, the main highlight of the conference was that ReSoURCE won the PHÖNIX award 2024. There is no question that it is an additional motivation boost when an independent jury recognizes the added value of the project to a more sustainable industry, and it highlights the excellent collaboration within the team. Apart from the beautiful statue, we also brought a lot of takeaways home – learnings about the newest legislations on the circular economy, obstacles when it comes to recycling mineral waste and even almost philosophical questions. After our talk, we had to answer: “What does the industry need to improve circularity: Carrots or Sticks?” Still a tough question to answer in my opinion.

After an eventful AWT2024, I had the opportunity to travel to Brussels for the EIT Raw Materials Summit 2024. Although I had already been to several conferences (mostly scientific or waste management on a national level), being at an EU summit with over 1000 participants and only C-level speakers having a professional moderator for all sessions, actually made me a little nervous. Especially because we had the opportunity to present ReSoURCE within a workshop organized by our project partner Crowdhelix. Attending two days of panel discussions was a not a new experience for me, but there was hardly any interaction with the audience, which is something I am used to at scientific conferences. I also have to admit that I felt more comfortable in the “Innovation Village” exchanging with a lot of start-ups presenting a very broad spectrum of innovative recycling solutions and during the workshop, getting in touch with the audience. Nevertheless, I was very happy to be able to attend this event and get a high-level view on the most relevant topics of our generation. In the end I think everyone agreed that we still have a lot to do and that actions need to be taken fast. Unfortunately answers to the “how” came up a little short for me.

My circular economy trips were rounded up by getting invited to talk at the BKMNA’24 in Berlin and present ReSoURCE to a smaller but more targeted audience. And yes, one can discuss a whole conference day about waste reaching its end-of-waste (meaning it is no longer waste but product), if “waste” is really “waste” or a “by-product”, etc. Making it evident how complex legislation might be and how difficult it can be to reintroduce valuable secondary raw materials into the circle.

After very exciting, fruitful but also exhausting months, I am really proud of being part of the project ReSoURCE and that I had the opportunity to highlight our share towards a more sustainable future on these platforms!

Authors’ Portrait

Simone Neuhold

Dr. Simone Neuhold currently works for RHI Magnesita. Before she joined the company she was hired at Pilkington Deutschland AG/NSG Group. Simone studied at the TU Graz Chemistry and Advanced Materials Science, and at the Montanuniveristaet Leoben Waste Management and Waste Processing Technologies. Her research interests are recycling of mineral wastes, materials science and oekodesign.

LSA – Laser Analytical Systems & Automation GmbH looks back on a successful twenty-year history and pursues a clear mission: through customised solutions, comprehensive process knowledge and the use of state-of-the-art laser technology, we make the entire material cycle – from raw material extraction to recycling – more efficient and sustainable. Our many years of experience and in-depth understanding of the industry enable us to develop turnkey solutions for the diverse and individual needs of our customers. As every company has unique requirements, we place great importance on working closely with our customers. Our goal is to provide solutions that meet current needs while being future-proof and scalable.

Our extensive knowledge and experience in laser technology, process automation and system integration are the key to our success. We use state-of-the-art laser technologies to perform precise and reliable analyses, which are crucial at all stages of the material cycle. One of the key technical elements we use is a multi-sensor approach that combines data from different sensors to enable more precise and comprehensive analyses. Different optical technologies, such as laser, infrared and camera systems, are used simultaneously. Each sensor records specific data, e.g. spectral information, geometric properties or thermal profiles. This data is integrated using advanced algorithms that combine, compare and analyse the individual sensor information. This creates a more detailed and accurate picture of the analysed object or process.

This approach significantly improves the detection and classification of materials, quality control and process optimisation. Another advantage of the multi-sensor approach is the increased robustness and reliability of the systems, as redundancies and errors of individual sensors can be compensated for by the others. Overall, this approach leads to greater efficiency and precision in applications such as industrial automation, material processing and recycling.

From raw material extraction to recycling, our technologies help to optimise processes and use resources efficiently. Precise and efficient analyses during raw material extraction help to optimise the mining process and maximise the quality of the raw materials obtained. In the production phase, the focus is on increased efficiency and the associated cost reduction through seamless monitoring of the quality and precision of the manufactured products. Our technologies enable companies to continuously monitor the quality of their products and ensure that they meet the highest standards.

In the area of recycling, our laser technologies support efficient processes by facilitating the separation and reutilisation of materials. Our innovations help to reduce our customers’ ecological footprint and conserve valuable resources. Our solutions are designed to promote sustainability and minimise environmental impact. By implementing our technologies, companies can not only increase their efficiency, but also make an important contribution to environmental protection.

Our vision is to remain at the forefront of technological development through continuous research and development and to drive innovation through passion and expertise. We continually invest in developing our technologies and researching new solutions to meet the ever-changing demands of the market. Our passion for innovation drives us to constantly find new and better solutions that offer our customers real added value.

To summarise, our goal is to increase efficiency and sustainability throughout the entire recycling cycle by using state-of-the-art laser technology and customised solutions. We are committed to supporting our customers in overcoming their challenges and helping them achieve their goals. With our extensive experience, in-depth knowledge and relentless innovation, we are the ideal partner for companies looking to optimise their processes and increase their competitiveness.

After two years of meticulous planning and development, we finally kicked off the mechanical assembly of our ReSoURCE sorting system in October-November 2023. The initial phase included setting up the conveyor technology, including conveyor belts, a vibration feeder, and a bunker, which were all expertly assembled by our supplier.

In early December, the much-anticipated containers arrived at LSA in Aachen. A massive 110-tonne truck-mounted crane was ready at the crack of dawn to lift the two containers onto our premises. With a combination of crane precision, forklift maneuvering, armored rollers, and a lot of dexterity, we positioned the containers in the assembly hall down to the millimeter.

With the containers securely in place, we moved on to installing the remaining components. First up was the extraction system, designed to handle dust extraction inside the containers and for the bunker, boasting an impressive suction power to avoid any major deposition of fines. This system takes up about a third of the first container, serving as the heart of our air conditioning technology. We laid extraction pipes across both containers and installed extraction points in dust-heavy areas. Additionally, a heat recovery system was set up in the sorting container to keep it warm during winter, ensuring the interior doesn’t cool down.

One of the key challenges was handling the limited space between the conveyor belts and to consider future dismantling when the machine will be shipped. Meanwhile, our team connected the conveyor belts and extraction system electrically, enabling us to begin operational testing. We ran smaller batches of refractory bricks through the system by hand, using particularly dusty samples to test and visualize the dust extraction process.

With the successful commissioning of these major components, we moved on to the installation of the measuring bridge and the first sensor components. The 3D image recognition and LIBS unit were our first targets, alongside the installation of the necessary control cabinets inside the container. Just in time for the M24 meeting, we achieved the first detections using the 3D object recognition and analyzed them with the LIBS unit.

In the coming weeks, we’ll be adding more components, including HSI cameras to the measuring bridge, delta robots, and a pneumatic air ejection unit for sorting. To ensure seamless operation, we’ll also be laying down several hundred meters of cable and measuring lines.

Stay tuned for more updates as our installation and commissioning is still in progress! We’ll share the latest developments in an upcoming blog post!

Author’s Portrait

Carsten Coenen

Carsten Coenen is a development engineer at LSA – Laser Analytical Systems & Automation GmbH (Germany) since 2022. He is working on the mechanical design and the implementation of high-precision 3D-printed parts for use in optical modules. Previously, he completed an apprenticeship as an electronics technician at RWTH Aachen University and received his B.Eng. Mechatronics and M.Sc. Mechatronics from FH Aachen University of Applied Sciences.

During his studies, he already worked as a working student at RWTH Aachen University and at AGVR GmbH (Germany). Since he joined LSA, he has also been involved in EU projects (e.g. REVaMP and ReSoURCE).

At ReSoURCE, we had the privilege of attending the EIT Raw Materials Summit in Brussels, where we participated in a dedicated Crowdhelix workshop alongside three other projects funded under the same call. “Accelerating the Adoption of Circular Strategies in the Raw Materials and Steel Industries” was moderated by Susana Xarà, the projects’ advisor, which delved into the key strategies and innovations necessary for advancing the circular economy and the recovery of raw materials.

The collaboration and insights shared were valuable, highlighting the collective effort required to drive sustainable practices in these critical industries. Our participation at the summit allowed us to engage with leading experts and peers who share our vision for a circular and resource-efficient future.

Highlights from the Crowdhelix Workshop

The first session featured an enlightening interview with Peter Tom Jones, who underscored the pressing need for an integrated and harmonized Industrial Green Deal. He emphasized the importance of adapting industrial practices to develop green technologies, which are essential for achieving climate neutrality. Peter Tom Jones highlighted that critical raw materials are vital for clean technologies and can be mined responsible within Europe, ensuring a sustainable supply chain.

In the second session, the EU-funded projects, Hephaestus, Rotate, RawMina and ReSoURCE, shared their insights, technologies, and expected impacts. Each project presented their objectives and showcased innovative technologies aimed at the groundbreaking approaches to recover raw materials. This session provided a comprehensive overview of how these projects are contributing to the circular economy and sustainable development.

Roundtable discussions: Circular Strategies and Industrial Synergies

The last part of the workshop consisted in roundtable discussions. This concluded with engaging discussions on circular strategies, industrial synergies, and transformative industrial practices. It has been a valuable experience great for engaging in meaningful conversations to provide takeaways at the societal, environmental and innovation levels. We were successful at engaging the audience and creating new connections for the future exploitation of the projects’ outcomes.

About the Raw Materials Summit

The EIT Raw Materials Summit is the largest and most active raw materials knowledge and innovation network, with 300 partner organizations spanning the entire race materials value chain and promoting the circular economy. The goal is to make Europe future proof and to secure the strategic raw materials supply necessary to deliver the Green Deal. As Europe requires large amounts of raw materials for the production of clean technologies, ensuring the supply of critical raw materials within the continent is key.

This event brought together the European Commission, EU member states and international leaders and policymakers, global industry leaders, financial institutions, start-ups, innovators, researchers, academics, and civil society organizations. Several panel sessions led to thought-provoking discussions, featuring insights from more than 65 speakers comprising industry and policy leaders and innovators, and nearly 1,000 attendees.

Author’s Portrait

Sofia Iriarte

Sofia is project ReSoURCE´s Science Communicator. She studied Advertising and Public Relations and has a MSc in Communication Science from the University of Vienna. Currently, she is part of the Innovation Management team and Global Communications at RHI Magnesita.

In a previous blog post “The Source of Light”, the working principle of a laser was described. The laser systems which will be used in the ReSoURCE Project were also mentioned, and today is the perfect opportunity to write about the differences between the two systems and the challenges faced.

The ReSoURCE laser systems, which will be used in Demonstrator A and B for LIBS measurements, emit pulses having of width of only a few nanoseconds. For the first system, 100 pulses per second (100Hz) and for the second 400 pulses per second (400Hz) are emitted. One could think that the only difference is the parameter of the repetition rate, and one would be (partially) correct. However, the increased repetition rate causes one main challenge: an increase of the thermal lensing within the laser medium.

As you can imagine no system has a 100% conversion efficiency. In the case of a laser, electrical energy is used to pump multiple diodes; these emit light at a wavelength of approximately 808nm. This specific wavelength is absorbed by the laser medium and excites electrons to a higher energy level. When falling back down to lower energy levels laser light is emitted. During the pumping process a lot of the energy is actually lost in the form of heat.

To avoid the laser medium being too warm, water flows around it to cool it down. Of course, since the water only flows on the outside of the laser medium, the heat is not evenly distributed: a temperature gradient is formed within the laser medium. The properties of the material cause a change in refractive index based on the temperature it has. The temperature gradient leads therefore to a gradient in the refractive index: it can be assimilated to being equivalent to a lens, hence the name “thermal lens”.

Lenses are present in many devices used daily: telescope, glasses, cameras and many more. These cause the object observed to either be bigger/smaller or more in focus. The same happens to the pulsed laser beam when it goes through the laser medium having a thermal lens: it gets smaller. By having a repetition rate of 400Hz instead of 100Hz, the temperature gradient is a lot wider within the laser system at 400Hz and therefore the thermal lens is also more present. To compensate, additional lenses needed to be used to avoid the pulsed beam being focused within the system, this was done successfully with promising results for later steps of the project.

Finally, the deliverable concerning the two laser sources was successfully submitted. The next step is to perform test trials using the laser systems at the LSA GmbH facility in Aachen. We will keep you posted with further updates!

Authors’ Portrait

Dorian-David Percheron

Dorian-David Percheron is a Development Engineer at InnoLas Laser GmbH, focused on the production of client-specific DPSS laser systems. He studied at the Technical University of Munich (TUM) and has a M.Sc. “Applied and Engineering Physics”. His research interests are Optics and Renewable Energies.

Paul Denck

Paul Denck is a part-time Development Engineer at Innolas Laser GmbHwho is interested in the field of electronics.

The European Green Deal aims to address the existential threat of climate change and environmental degradation by transforming the EU into a modern, resource-efficient, and competitive economy. It sets ambitious goals, including achieving net-zero greenhouse gas emissions by 2050, decoupling economic growth from resource use, and ensuring inclusive progress leaving no one and nothing behind.

It outlines a transformative shift towards a climate-neutral continent by 2050, with member states committed to reducing emissions by at least 55% by 2030. This initiative promises various benefits, including opportunities for innovation, investment, and green jobs creation.

The green transition presents a major opportunity for European industry by creating markets for clean technologies and products. For this reason, the Green Industrial Plan was introduced to boost Europe´s net zero industry and to accelerate the transition to climate neutrality. To secure Europe’s place as the home of industrial innovation and clean tech, massive investments must be made in funding research and innovation.

Driving European R&I to Accelerate the Roll-out of Strategic and Sustainable Tech Deployment

Horizon Europe is the EU’s key funding programme for research and innovation (R&I). To step up the technological developments, the EU has invested 40 billion in R&I for the European Green deal. EU investments in these fields play a pivotal role in fostering the development of technologies that support the growth of more sustainable industrial value chains through Europe.

One such initiative, the ReSoURCE project, has attracted significant attention due to its potential impact on industry transformation and revolutionary advancements in refractory recycling. With the capacity of broader application beyond its initial scope, the project holds promise for revolutionizing recycling processes in the industry.

Given the high carbon intensity of the refractory industry, reducing CO2 emissions is crucial. The utilization of secondary raw materials presents an opportunity to mitigate impact, particularly by reducing extractive processing in raw materials mines. Through innovative recycling methods of spent refractories, substantial CO2 savings can be achieved. However, enhancing the efficiency of recycling processes requires the development of new technologies, particularly in automated sorting solutions.

The ReSoURCE consortium is actively engaged in innovating the full process chain of refractory recycling with AI-supported multi sensor sorting equipment as its core technology. Through these efforts, ReSoURCE contributes to advancing circular economy principles and supporting the transition to a more sustainable industrial landscape.

ReSoURCE will join the EU Missions and cross-cutting activities info days to gain more insights on how our project can further contribute. If you are interested in funding opportunities helping to reach the EU mission goals in the areas of climate and the environment and would like to contribute bringing concrete solutions to some of the greatest challenges facing our society, then join this event on April 25-26. The event aims to inform potential applicants about the new topics included in the EU Missions and Cross-cutting Activities work programme 2024.

Author´s Portrait

Sofia Iriarte

Sofia is project ReSoURCE´s Science Communicator. She studied Advertising and Public Relations and has a MSc in Communication Science from the University of Vienna. Currently, she is part of the Innovation Management team and Global Communications at RHI Magnesita.

We use a variety of different analysis methods in our project, which we would like to introduce to you in this format. After presenting the XRF analysis method in the last article of this series, we would now like to introduce you to the scanning electron microscope (SEM). SEM is a powerful tool used in scientific research and industry to measure the chemistry of points of interest, examine the surface of materials at high magnification or to create element distribution maps of a sample. It works by using a beam of electrons to scan the surface of a sample, producing detailed images that reveal the structure and composition of the material.

Similar to XRF, the elemental analysis of the SEM also works with energy dispersive X-ray spectra, also known as EDX. In brief: A mineral grain of interest is bombarded with electrons; an electron close to the core is knocked out of its position; the gap is filled by an electron from a higher orbital and must release energy when changing position, this energy is element-specific. This allows researchers to identify the elements present in the sample and determine their relative concentrations.

We use this method in environmental and waste mineralogy. For example, it is used to analyse the distribution of pollutants in mineral waste or to test individual mineral grains for their pollutant content. With the SEM results, we can also determine minerals, and subsequently estimate whether pollutants are firmly bound and therefore immobile or less firmly bound and therefore mobile. This important finding supports us, in the search for new alternative applications of the analysed material.

However, since pollutants do not play a role in spent refractory materials, we have focused on those elements that can directly hinder the further recycling of spent refractories. With SEM, we have created so-called element distribution maps (Figure 1, right). By evaluating these maps, we can make statements about the distribution of elements that might hinder the further recycling process like potassium (K). Other than that, we can also have a look on the distribution of recycling mineral phases and determine their size, their chemical content as well as their intergrowth structures. This helps us to optimise the recycling process.

Author´s Portrait

Florian Feucht

DI Florian Feucht, is research associate at the Chair of Waste Management and Waste Treatment at the Montanuniversitaet Leoben, and part of the Workgroup: “Environmental remediation and mineral waste”. Since 2023 he participates in the Montanuniversitaet’s PhD Program. From 2018 to 2023 he studied “applied geoscience” at the Montanuniversitaet Leoben and wrote his master thesis about “Chemical-Mineralogical Characterization of Ladle Slag from voestalpine Linz”. From 2014 to 2018 he studied at the University of Vienna Earth Sciences and wrote a bachelor thesis on the subject: “Petrological and Petrographical Ínvestigation of Mafic-, Ultramafic Rocks from the Dunkelsteinerwald, Gföhler Unit, Moldanubic” Florian’s research interests are chemical-mineralogical characterisation of mineral wastes, Mineralogy, Slag mineralogy, Recycling and Waste Management.

How can we reach climate neutrality, secure raw materials, and maintain a good quality of life on our planet for future generations? One thing is clear: we need to shift from a linear resource-intensive economy to a circular one. This is crucial for Europe to achieve carbon-neutrality by 2050, where society as a whole and stakeholders are embracing the “closing the loop approach”.

The circular economy approach is an enabler of economic growth and development while simultaneously reducing carbon emissions and achieving the green transition. It aims at a zero-waste life cycle of products and hence the preservation of natural resources. Translated into the field of refractories, this implies the extensive reuse of refractory materials that have already been in operation.

For every tonne of recycled refractory material that is re-used, approximately 1.5 tonnes of CO2 emissions are avoided compared to the processing of virgin raw materials. Furthermore, recycling refractory materials prevents waste disposal, reintegrates secondary raw materials into the economy, and diminishes reliance on virgin raw materials.

However, recycling spent refractories poses several challenges. From sourcing to processing and utilization, various obstacles must be overcome. Among several challenges that are faced, the sorting and cleaning stage is particularly demanding. Sorting the various products is crucial for attaining the required chemical composition to either repurpose the materials in refractories or direct them for additional processing.

Currently, the sorting stage represents the foremost hurdle to overcome, as it predominantly relies on manual operations and the expertise of the workforce to distinguish between different types. Manual sorting is largely dependent on experienced personal to select the material, by relying on color, fracture characteristics, sound upon impact, and density. This poses challenges due to the limited distinction possible with the finite discernment capabilities of human senses.

In light of these obstacles, innovative solutions are required, from sorting during or after dismantling, contaminant removal or stabilization, and fragmentation methods to enhance mineral circularity. To enable the sorting process´s efficiency, fully automated identification and separation systems is an imperative and a strategic development step. Therefore, Refractory Sorting Using Revolutionizing Classification Equipment (ReSoURCE) project aims to innovate the entire process chain.

The technologies developed for the recycling of spent refractories in ReSoURCE will revolutionize the status quo of spent refractories sorting. By enhancing efficiency in the recycling process, we can reduce up to 800,000 tonnes of landfilling, resulting in significant CO2 savings. Additionally, this initiative will lead to substantial energy savings and will also strengthen Europe´s raw material resilience.

Research and innovation are crucial to offering a pathway towards achieving Europe’s climate neutrality objectives. Through the adoption of circular economy principles and the embrace of innovative solutions, the recycling of raw materials derived from refractories presents a tangible and effective strategy for reducing carbon footprints and advancing sustainability goals.

Author´s Portrait

Sofia Iriarte

Sofia is project ReSoURCE´s Science Communicator. She studied Advertising and Public Relations and has a MSc in Communication Science from the University of Vienna. Currently, she is part of the Innovation Management team and Global Communications at RHI Magnesita.