Our Sorting Unit

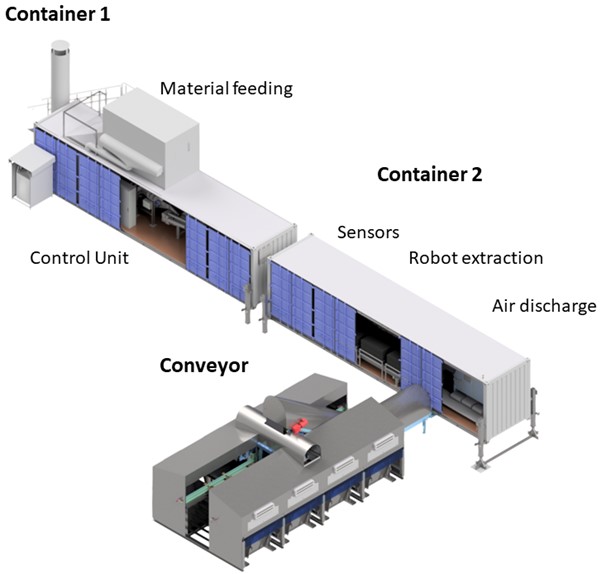

Today, we finally can present the construction of our sorting unit. In the picture you can see the design of the plant.

Container 1, the left part in the illustration, houses the material feed and the supply unit. The supply unit includes components such as the dust extraction system and the compressor components. The so-called feeding container also has an opening in the roof through which the material can be fed into the bunker by a wheel loader. To protect the opening against environmental influences such as rain, a folding roof is provided.

The material, lying in the bunker, is singularized and transported further by an adjustable vibratory conveyor. Singularization is an essential task in this context because subsequent measurement is only possible when particles do not overlap or touch each other. After this is done, the material is conveyed to the second container, the sorting container, via a conveyor belt.

In the second container, the material is moved over a large conveyor belt. In the left part of the container are the sensors which are needed for the geometric measurement on the one hand and for the analysis of the particles on the other hand. For the geometric measurement a 3D camera scans the bricks and send the position information to a LIBS sensor, that focuses on the surface of the bricks and measures there the material composition.

As soon as the brick fragments have been measured, an AI classifies them into categories. After classification, they are discharged by robots into bins or blown out by compressed air by a blow-out unit. The robots eject larger particles and the air blast unit ejects the smaller ones.

The fractions can be discharged individually via a system of conveyor belts and collected in large bins. These bins can then be emptied using a forklift or front wheel loader.

We know, it is still a while, but we are already looking forward to seeing it in action.

Author’s Portrait

Carsten Coenen

Carsten Coenen is a development engineer at LSA – Laser Analytical Systems & Automation GmbH (Germany). He is working on the mechanical design and the implementation of high-precision 3D-printed parts for use in optical modules. Since 2022 he has been working at LSA. Previously, he completed an apprenticeship as an electronics technician at RWTH Aachen University and received his B.Eng. Mechatronics and M.Sc. Mechatronics from FH Aachen University of Applied Sciences.

During his studies, he already worked as a working student at RWTH Aachen University and at AGVR GmbH (Germany). Since he joined LSA, he has also been involved in EU projects (e.g. REVaMP and ReSoURCE).

Partner