The Pow(d)er of SINTEF

Our powder technology activities at SINTEF have 40 years of history working with a large range of industrial applications such as Oil & Gas, Mining & Mineral Processing, Marine, Food & Feed and FMCGs etc. The solutions we developed over the years have been covering several powder processing operations such as transportation (pneumatic and mechanical), fluidization, mixing, separation, classification, and comminution etc. The ReSoURCE project gives us an opportunity to use our experience and expertise to develop solutions for the recycling of refractory materials.

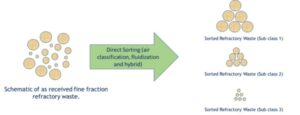

Currently, in refractory recycling, the fine fractions are mostly used as landfill. However, it has great potential to be reused in refractories or other downcycling applications. The challenge is to recover these fine fractions from the refractory waste through direct sorting methods. In ReSoURCE, we are developing direct sorting solutions for the fine fractions (< 5mm) of refractory waste.

Schematic diagram representing the sorting of refractory waste into sub-classes for reuse in refractories/downcycling applications:

Separation of fine fraction is very different compared to the coarse fractions due to enhanced particle-particle interactions. While doing separation, we basically separate the entities with different properties such as morphological, electrical, and magnetic properties etc. For example, particle with different sizes interact differently with air stream. Same with the particles with different magnetic properties with interact differently to an applied magnetic field.

We plan to use various methods such as air classification, fluidized separation, and some hybrid approaches to separate fine fractions into sub-classes to develop a pilot scale solution. The solution will be implemented to an industrial scale demonstrator in the later stage of the project.

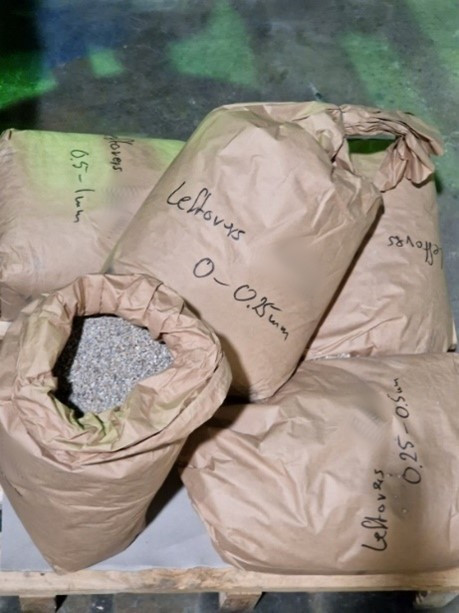

The samples from RHI Magnesita are arrived at the facilities of SINTEF and our Lab Team (Kristin Søiland and Franz Otto von Hafenbrädl) and the powder test hall are ready for the experimental work. We are looking forward to the results and turning them into successful demonstrators and achieving the project objectives! And of course, we will keep you updated regarding our progress on this blog.

Author’s Portrait

Chandana Ratnayake

Dr. Chandana Ratnayake is working as a Chief Scientist in SINTEF, Norway. He possesses a PhD in Process Technology, specialising in Powder & Particulate Technology from Norwegian University of Science and Technology (NTNU), Norway. He is an expert on Powders and Bulk Material Technology- storage, transport, processing, and characterisation of particulate materials; system design, optimisation and troubleshooting with more 15 years of experience. Chandana has been working in many research, innovation, and development projects, funded by Norwegian Research Council, EU and direct industrial contributions. He has published his R&D contributions in many international refereed journals, conferences, and seminars. He is the Norwegian representative of the Working Party on Mechanics of Particulate Solids in EFCE (European Federation of Chemical Engineering). Chandana also works as a Professor II (Adjunct Professor) in the University of South-Eastern Norway (USN).

Author’s Portrait

Akhilesh Kumar Srivastava

Dr. Akhilesh Kumar Srivastava is a Senior Scientist at SINTEF (Norway). Currently, his activities are mainly focussed on digital transformation of process industries and digitalized manufacturing. He is the project manager of two European Union Horizon 2020 projects, COGNITWIN and DIY4U. Prior to joining SINTEF, he worked at Miljøbil Grenland (Norway) and Risø DTU National Laboratory for Sustainable Energy (Denmark). He also served Visiting Scientist positions at ERI@N (Singapore) and Elettra Sincrotrone Trieste (Italy). Akhilesh received his M.Tech. from IIT Bombay (India) and Ph.D. from NTU (Singapore). He also attended Executive Education program at MIT Sloan School of Management (USA).

Partner