Once again samples are taken…

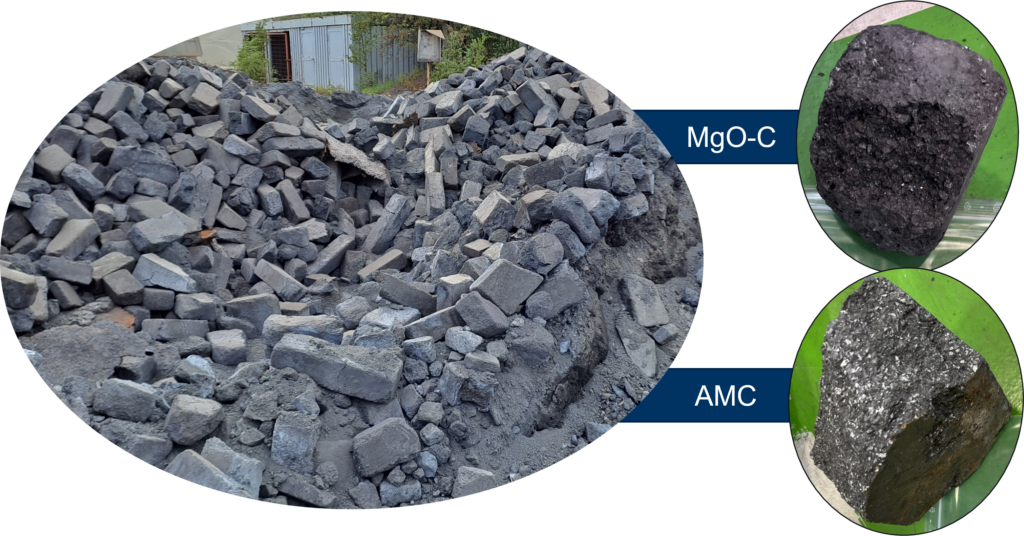

One might think that last year we took and analyzed more than enough samples to have sufficient material to train the sensors for the automated sorting system. But an essential piece of the puzzle was still missing: a certain type of refractory brick that RHI Magnesita installs in steel casting ladles. So far we have only been able to sample used MgO-C bricks (as Stefan Heid explained in his blog post Appearances are Deceptive), but not used alumina-magnesia-carbon bricks (AMC, i.e. alumina-based bricks with carbon bonding). However, separating these types is extremely important, as incorrect throws and thus contamination in our recycled secondary raw materials lead to problems in the production of new bricks.

Since AMC bricks are rarely delivered to our MIRECO location in Mitterdorf, we went to a MIRECO site in Bremen for our fourth sampling campaign. There, my colleague Florian Feucht (Montanuniversität Leoben) and I were not able to visit the beautiful Hanseatic city of Bremen, but we were able to plan the sampling of almost 6 tons of material and gain very interesting insights into on-site recycling. Unlike in the recycling center, where different breakout materials from different customers (steel and cement industries) are sorted and processed, in on-site recycling only the material from one customer is sorted. In Bremen, the sorting was done directly at the steelworks and the majority of the material was reused for various products, e.g. metallurgical additives. This is also a clear difference, as the material from the recycling center is largely used in our own refractory products. Like in the recycling center, some of the breakout material must also go to landfill. This can be for various reasons, e.g. material that is too fine or cannot be sorted sufficiently.

We also had to approach sampling in Bremen a little differently than in Mitterdorf. Since there were only two of us on site this time, manual sampling of a 150 t pile was not realistic without severely disrupting ongoing operations. It was therefore agreed that this time the sampling would be carried out directly from the conveyor belt of the sorting system. Adjusted to the full amount of breakout material, a total of 6 big bags were filled with unsorted bricks at regular intervals. This ensured that samples from all different parts of the pile were shipped to us in Austria. We are very excited to see what valuable insights we can gain from this sampling for automated sorting.

Another interesting aspect of our trip was an impromptu crash course in hand sorting MgO-C and AMC stones. A visual comparison of the two types makes it clear where the challenges lie in hand sorting. In short, to us, at first glance, everything in the pile looked the same. Nevertheless, in Bremen we were shown how even these two difficult-to-distinguish varieties can be separated manually with a lot of experience. Here it is above all the details that make the difference. For example, AMC bricks are more compact and therefore usually less broken after breaking out of the ladle than MgO-C bricks; The original format (i.e. the original size of the stones) is usually easier to recognize than with MgO-C stones. AMC stones are also harder to break and sound different when struck with a hammer. However, despite our crash course and the efforts on site to introduce us to the depths of hand sorting, we will play it safe and continue to rely on chemical analyzes for our further experiments. In any case, this visit showed us once again how much experience is necessary for solid hand sorting and how complex the recycling of refractory bricks is.

Author’s Portrait

Simone Neuhold

Dr. Simone Neuhold currently works for RHI Magnesita. Before she joined the company she was hired at Pilkington Deutschland AG/NSG Group. Simone studied at the TU Graz Chemistry and Advanced Materials Science, and at the Montanuniveristaet Leoben Waste Management and Waste Processing Technologies. Her research interests are recycling of mineral wastes, materials science and oekodesign.