After 42 months of intensive collaboration, the ReSoURCE project (Refractory Sorting Using Revolutionizing Classification Equipment) has reached a successful conclusion. As a Horizon Europe initiative bringing together leading partners from research and industry, ReSoURCE stands as a testament to what coordinated European innovation can achieve.

Launched in June 2022 and running until November 2025, the project brought together a consortium of nine internationally renowned partners, supported by an €8.5 million budget, including €6 million in funding from the European Commission. Together, the partners set out to revolutionize the recycling of spent refractories — a critical but traditionally under-addressed material stream in energy-intensive industries.

Breakthrough Results for Circular Raw Materials in Europe

The consortium successfully delivered all planned outcomes, including the development and demonstration of next-generation sensor-based sorting technologies designed to significantly improve the efficiency, quality, and economic viability of refractory recycling. These advances open the door for higher use of secondary raw materials, reduced dependence on primary resources, and meaningful contributions to CO₂ emission reduction across industrial value chains.

Beyond the technological innovations, ReSoURCE strengthened collaboration between academia, technology developers, and industrial users — creating a robust foundation for future European efforts in circular raw material management.

Final Event in Brussels Highlights Impact and Future Directions

On 17 November 2025, the consortium gathered in Brussels for the ReSoURCE Final Event, joined by stakeholders from across Europe and representatives from the European Health and Digital Executive Agency (HaDEA). The event showcased key results, industrial case studies, and strategic perspectives on the future of circularity in heavy industries.

A closing panel discussion underscored the broader significance of the work accomplished. Speakers emphasized that EU-funded projects like ReSoURCE demonstrate the power of uniting research excellence, industrial ambition, and European policy goals to accelerate green and digital transformation.

Contributing to Europe’s Green and Industrial Agendas

ReSoURCE’s achievements directly support the objectives of the European Green Deal and the emerging EU Clean Industrial Deal, both of which call for rapid decarbonisation, strengthened strategic autonomy, and leadership in circular economy innovation. The project illustrates how breakthrough recycling technologies can reinforce Europe’s resilience while enabling industry to remain competitive during the transition to climate neutrality.

A Model for Collaborative Innovation

ReSoURCE demonstrates that collaboration across material science, digital sensing, industrial manufacturing, and recycling can lead to practical solutions that support systemic improvements in circular raw material management.

The consortium’s success provides a strong platform for future initiatives aimed at scaling circular raw materials, reducing environmental footprints, and supporting a sustainable industrial transformation across Europe.

More pictures from the final event here.

Author’s Portraits

Sofia Iriarte

Sofia is project ReSoURCE´s Science Communicator. She studied Advertising and Public Relations and has a MSc in Communication Science from the University of Vienna. Currently, she is part of the Global Communications team at RHI Magnesita.

Conveyor belt systems are crucial in many modern industry applications. From recycling to manufacturing and food processing, they move, sort, and inspect materials at high speed, replacing heavy manual effort with continuous, reliable throughput. In the ReSoURCE project, we are taking this a step further: adding advanced sensing so that sorting isn’t just about size or shape, it’s about the identification of material composition.

At the heart of this capability is hyperspectral imaging (HSI). Unlike conventional RGB cameras that record three broad colour channels, HSI captures hundreds of narrow spectral bands across the visible, near-infrared (VNIR), and short-wave infrared (SWIR) ranges. Each material reflects light in a characteristic way, its so-called spectral fingerprint, allowing for a precise, fast identification directly on a moving belt.

We have previously shared the laboratory groundwork behind this approach, i.e. sensor characterisation, algorithm tuning, and material libraries. You can find out more in posts such as NEO visit in Leoben in October 2023, Predicting Refractory Brick Types with our HySpex VNIR-SWIR Cameras, Shining a Light on Raw Materials, and Our Samples in the Light of Science. With that foundation in place, this article focuses on bringing HSI from laboratory to real-world application inside the RAPTOR system.

NEO, HySpex, and the Technology behind HSI

Based in Norway, Norsk Elektro Optikk (NEO) has developed optical instruments for more than four decades. Through our HySpex division, we design and manufacture high-performance hyperspectral cameras trusted by researchers and industry worldwide. HySpex systems are known for high spectral and spatial resolution, low noise, and excellent optical quality, delivered in robust platforms that operate reliably in the lab, in the field, on aircraft, and in industrial applications.

This versatility is why HySpex cameras are used across industrial monitoring, system development, and research, reaching from geoscience and environmental mapping to quality control in manufacturing and advanced materials analysis. Beyond ReSoURCE, NEO contributes to initiatives like M4Mining, where hyperspectral imaging supports responsible mineral exploration and resource characterisation.

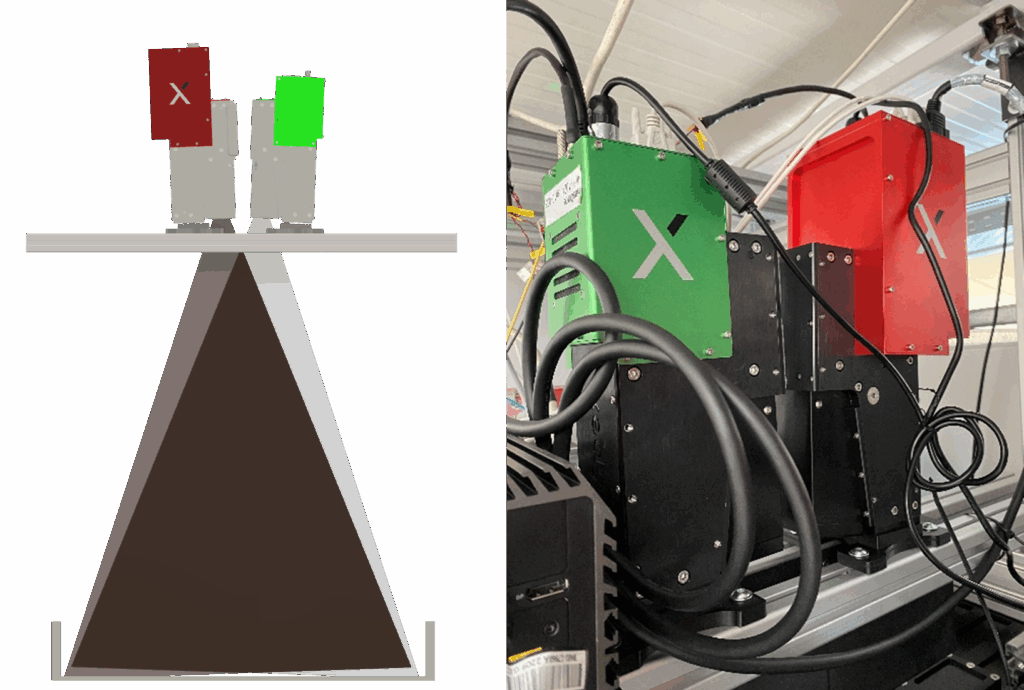

Figure 1. Hyperspectral cameras on Demonstrator A. Left: diagram used for designing the module. Right: Cameras installed onsite. The red camera is a HySpex SWIR 384, and the green one a HySpex Baldur 1024 N.

NEO’s Role in ReSoURCE

Within ReSoURCE, NEO provides both equipment and expertise. The RAPTOR sorting line integrates two HySpex cameras, a Baldur VNIR V-1024N and a Classic SWIR-384, together covering the wavelength range of 400–2500 nm. Our team also contributes geological insight and chemometrics know-how, ensuring that spectral data translates into dependable, application-ready material classes on the conveyor (read more about NEO´s role in this project).

From Calibration to Classification – HSI on the RAPTOR Conveyor

Moving from the lab to the line starts with a simple but crucial step: reflectance calibration. Before measuring sorting material, the system records a calibrated white reference image. This enables accurate conversion of raw sensor data into absolute reflectance, which is essential for stable modelling and inference.

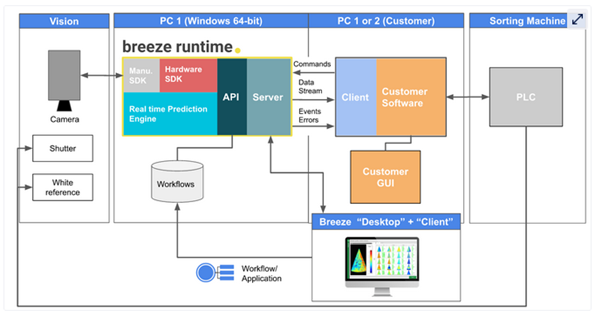

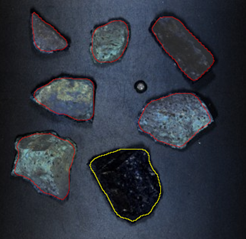

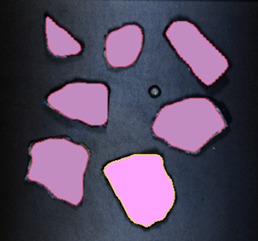

Once running, the belt is scanned continuously. The chemometrics software Breeze (Prediktera) converts the incoming image stream into reflectance and performs automatic segmentation, removing the background so that only the material particles remain. For the current use case, the analysis targets particle sizes between 20 and 120 mm. Each detected fragment is then classified according to its spectral fingerprint.

Figure 2. Integration schematics for HS camera, Breeze analysis SW and third-party SW for controlling or receiving results from the analysis process. In Demonstrator A, there are 2 “Clients”: the general DA interface and the ROI module

To ensure consistent, uniform illumination across both cameras’ fields of view, the HSI setup uses four 150 W halogen lamps aimed at a narrow common area on the conveyor. The lighting assembly is mounted beneath the measurement bridge for thermal isolation and is encapsulated to withstand dust generated by the material stream. This combination stabilises the radiometric conditions and improves repeatability in a real industrial environment.

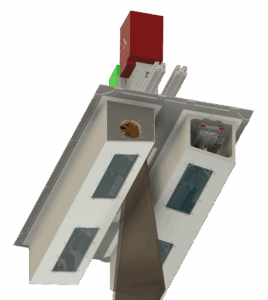

Figure3. Custom illumination system consisting of 4 halogen, broadband lamps. Left: diagram used for design and integration. Right: lamps installed on Demonstrator A.

Sensor Fusion: HSI + 3D Recognition + LIBS

RAPTOR is built around sensor fusion, combining complementary strengths for reliable, in-line decisions:

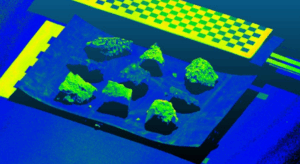

- HSI identifies material classes from spectral fingerprints in real time.

- A 3D recognition module captures the XY position and geometry of each particle on the belt, ensuring every object can be tracked and addressed precisely.

- The LIBS (Laser-Induced Breakdown Spectroscopy) unit receives both the object’s position and the HSI-predicted class. By firing a brief laser pulse and analysing the resulting plasma emission, LIBS provides elemental confirmation of the material, closing the loop between spectral prediction and chemical verification.

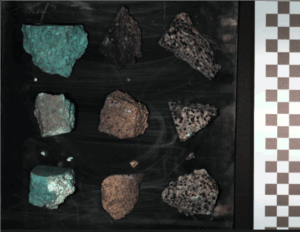

Figure 4. RGB picture of refractory samples (right) and a corresponding 3D image generated using a laser profiler (left).

General Characteristics of the Instrument – Built for Real-World Use

HySpex cameras in the RAPTOR combine fine spectral sampling (VNIR + SWIR) with high spatial fidelity and stable radiometry, which is critical for conveyor-based analytics. The optics are designed to minimise aberrations, the detectors offer excellent signal-to-noise performance, and the systems integrate neatly with other industrial software and hardware. In practice, that means consistent measurements, robust operation, and data you can model on. Whether you’re developing algorithms, running pilot lines, or deploying at scale.

Applications Across Industry, Development, and Research

Because HSI recognises material composition rather than appearance alone, the same core instrument supports many domains:

- Industrial: in-line sorting, quality assurance, process monitoring, and automated decision support.

- Development: rapid prototyping of new sorting strategies, material library expansion, and model transfer from lab to line.

- Research: geological mapping, environmental monitoring, precision agriculture, and materials science, often feeding insights back into industrial practice.

Figure 5. Left: SWIR image with segmented samples of material class HERC_highFe. Right: ground truth category displayed as an overlayed mask.

Looking Ahead

What makes RAPTOR compelling is not just the technology, but the impact: a practical path to sorting by composition at conveyor speeds. By combining HySpex hyperspectral imaging with 3D recognition and LIBS verification, the ReSoURCE project shows how advanced sensing can make recycling more efficient, more accurate, and more sustainable.

For NEO, it’s a natural extension of what we do: delivering precise, reliable measurements and the expertise to turn them into working solutions, on the factory floor as well as in the field.

Author’s Portraits

Justus Constantin Hildebrand

Justus Constantin works at HySpex by Norsk Elektro Optikk AS as a Hyperspectral Application Eng

Justus Constantin Hildebrand works at HySpex by Norsk Elektro Optikk AS as a Hyperspectral Application Engineer. HySpex is the industry-leading brand for airborne and ground-based hyperspectral imaging and a manufacturer of advanced electro-optical instruments.

He holds a background in Geography and Remote Sensing, having earned his Bachelor’s and Master’s degrees at Freie Universität Berlin and Humboldt Universität zu Berlin. During his studies, he worked extensively with hyperspectral cameras at the GeoForschungsZentrum Potsdam (GFZ), where his interest in the field deepened. In September 2023, he joined HySpex in Oslo, where he continues to work within the hyperspectral imaging domain.

At HySpex, Justus is involved in a wide range of industrial projects and applications, contributing his expertise across different sectors, including his participation in the Resource project.

ineer. HySpex is the industry-leading brand for airborne and ground-based hyperspectral imaging and a manufacturer of advanced electro-optical instruments.

He holds a background in Geography and Remote Sensing, having earned his Bachelor’s and Master’s degrees at Freie Universität Berlin and Humboldt Universität zu Berlin. During his studies, he worked extensively with hyperspectral cameras at the GeoForschungsZentrum Potsdam (GFZ), where his interest in the field deepened. In September 2023, he joined HySpex in Oslo, where he continues to work within the hyperspectral imaging domain.

At HySpex, Justus is involved in a wide range of industrial projects and applications, contributing his expertise across different sectors, including his participation in the Resource project.

Alongside its work on developing technologies for refractory recycling, the ReSoURCE project has also focused on cooperation with research and educational programmes — a key component of EU-funded projects. This work helps ensure that knowledge gained through the project is shared widely and that future professionals in the raw materials sector are equipped with relevant skills and insights.

Integration into Academic Programs

ReSoURCE has been included in a range of undergraduate, master’s, and doctoral programmes across partner institutions such as Montanuniversität Leoben (MUL), SINTEF, and Fraunhofer ILT. Project-related content was introduced in lectures, seminars, and supervised theses across study areas including:

- Mineral Processing and Circular Engineering

- Environmental and Climate Protection Technology

- Raw Materials Engineering

- Mechanical Engineering and Applied Geosciences

At least six lectures now include ReSoURCE-related content, such as Environmental and Waste Mineralogy, Fundamentals of Mineral Processing, and Introduction to the Processing of Particulate Solid Matter. These courses allow students to engage with practical examples and challenges directly connected to current research.

Support for Early-Career Researchers

The project has created opportunities for students and early-stage researchers at different academic levels, including:

- Two early-stage researchers (doctoral and postdoctoral) working on waste management and electrodynamic fragmentation

- Seven student theses (five master’s and two bachelor’s) on topics such as sensor fusion, refractory characterization, and comminution technology

- Two internships focusing on advanced processing technologies and life cycle assessment (LCA)

- These activities have provided valuable hands-on experience and contributed to the development of new knowledge within the project.

Outreach and Public Engagement

ReSoURCE was also presented in several events aimed at students and the wider public. Examples include:

- The PROMISE Scientific Exchange Day and Summer School, introducing students to current mineral processing research

- The Youth Entrepreneurship Week, hosted by RHI Magnesita, where the project was presented as an example of collaboration between academia and industry

- The Long Night of Museums and the Ecoality Climate Camp, which brought research topics into dialogue with younger audiences

- Through these events, the project has reached diverse groups, encouraging interest in sustainability, recycling, and the circular economy.

Future Outlook

Some of the project’s technical developments, such as AI-assisted sorting, electrodynamic fragmentation, and life-cycle approaches, may continue to influence how sustainability and resource efficiency are addressed in future curricula. By linking research with teaching, the project helps to ensure that students are introduced to innovative methods and real-world applications at an early stage in their education.

Conclusion

The cooperation with research and education has been an integral part of ReSoURCE’s work. Beyond the technical achievements, this collaboration reflects the project’s commitment to preparing the next generation of experts who will continue advancing circularity in raw materials.

A full overview of these activities can be found in the deliverable D11.4 – Report on cooperation with research and educational programs, available in the Knowledge Vault.

Author’s Portraits

Sofia Iriarte

Sofia is project ReSoURCE´s Science Communicator. She studied Advertising and Public Relations and has a MSc in Communication Science from the University of Vienna. Currently, she is part of the Global Communications team at RHI Magnesita.

On June 26, 2025 the webinar titled “Unlocking Circular Potential: Refractory Fillers in Advanced Composites” was organized by the ReSoURCE project in collaboration with RHI Magnesita, CPI, and Crowdhelix. Materials scientists, business representatives, and innovators convened virtually to talk about how recycled refractory materials might provide high-performance, environmentally friendly solutions for the composites industry.

Alexander Leitner, ReSoURCE Project Coordinator at RHI Magnesita, opened the webinar by outlining the goal of the project and described how the project is using automated, sensor-based sorting technologies that integrate Artificial Intelligence (AI), Hyperspectral Imaging (HSI), and Laser-Induced Breakdown Spectroscopy (LIBS) to address the challenges associated with recycling refractory.

The technological development of the project’s two recycled filler products, mRefCem and mRefFerro, was thoroughly examined by Ananda Roy, Yugal Rai, and Jack Maxfield from CPI. They shared information on the products’ physical characteristics, processing techniques, and performance in various applications. Part of the conversation was mediated by Claire Defty (CPI), who also pointed out possible avenues for industry adoption. The Circular Industry Helix, a platform created to link researchers, businesses, and innovators interested in using these materials at scale, was presented by the last speaker, Cais Jurgens from Crowdhelix.

CPI Team presented the material passports (mRefCem and mRefFerro) encompassing particle size distributions, densities, thermal and dielectric properties, and thermogravimetric profiles. In order to increase compatibility with different polymer systems, they also talked about surface modification techniques that use silanes (GLYMO, APTES).

The results of application testing were impressive: Epoxy composites improve fire resistance by reducing peak heat release and extending ignite periods in comparison to unfilled resin. Thermoplastic composites: mRefFerro provided remarkable stiffness and thermal stability in virgin HDPE, PP, and recycled PP, while mRefCem provided a well-balanced combination of strength and flexibility. Both performed on par with or better than conventional CaCO3 fillers. Better print quality, adhesion, and dispersibility are achieved with dielectric inks, opening the door for environmentally friendly printed electronics applications.

Impact on the Environment and the Market

About 1.5 tons of CO₂ can be saved per tonne of recycled refractories when they are used instead of virgin raw materials. Environmental Product Declarations (EPDs) and Life Cycle Assessments (LCAs) are being used by industry partners to quantify these savings and show consumers the environmental benefits.

It can be concluded from the webinar that the ReSoURCE Project’s strategy is progressing from concept to solutions that are ready for the market. The research is proving that recycled refractories may perform better than traditional fillers in terms of sustainability and performance parameters, as the mobile, AI-driven LIBS/HSI sorting system approaches maturity and shows promising application results in thermosets, thermoplastics, and dielectric inks.

During the Q&A, industry participants expressed interest in supply-chain integration and pilot trials, especially in the electronics, automotive, and construction sectors. In order to speed up industrial adoption, the following phase will concentrate on finalizing LCAs and EPDs, scaling manufacturing, and strengthening cooperation through the Circular Industry Helix.

Next Steps

The main takeaway of the event was a noticeable change in viewpoint: spent refractories should be seen as a valuable secondary resource with substantial commercial and environmental potential rather than as an expensive industrial waste stream that is headed for landfills. These materials can be converted into high-performance fillers that meet or surpass the technical requirements of virgin alternatives by implementing sophisticated, mobile sorting systems that integrate LIBS, HSI, and AI, along with focused material processing and application-specific development. In addition to lowering dependency on basic raw materials and related CO₂ emissions, this creates prospects for their application in a variety of industries, including infrastructure, automotive, electronics, and sustainable manufacturing. In addition, Cais Jurgens from Crowdhelix concluded by inviting participants to become a part of the Circular Industry Helix and take part in co-development projects; The platform allows businesses, researchers, and innovators to explore collaborative research projects, pilot studies, and co-development projects that expedite the use of recycled refractories and integrate the concepts of the circular economy into industrial supply chains.

If you are interested in learning more, watch the webinar recording available in our YouTube channel:

Webinar Recording: Unlocking Circular Potential: Refractory Fillers in advanced Composites

Authors’ Portrait

Hamza Cinar

The 17th International Conference on Materials Chemistry (MC17) took place from 7th to 10th July 2025 in the historic city of Edinburgh, UK. Hosted at the Edinburgh International Conference Centre (EICC), just a 15-minute walk from the iconic Edinburgh Castle.

This year’s edition marked a milestone for the MC series: it was the largest conference to date, boasting a record number of abstract submissions and welcoming over 600 delegates from across academia, industry, and research institutions. The scientific programme was structured around four core themes:

- Functional inorganic materials

- Nano and porous materials

- Soft matter and biomaterials

- Materials for energy and sustainability—including recycling, and critical materials usage.

Each theme was supported by a range of oral presentations and poster sessions.

Some of the talks I particularly enjoyed included:

- Recycling of battery materials using bioengineering

- Using machine learning to aid and complement classical materials discovery and optimization techniques

- Using X-ray diffraction computed tomography (XRDCT) to assess CO2 conversion and hydrogen production catalysts

The evening poster sessions were a particular highlight. The relaxed atmosphere encouraged great discussion and offered a platform to share ideas and receive feedback. Discussing my work with fellow researchers and experts provided valuable insights and fresh perspectives. The posters featured a diverse range of topics. I was particularly drawn to several posters focusing on sustainable materials, which included:

- Development of recyclable, biodegradable, and bio-renewable polymers

- Lignin valorisation for use in batteries, supercapacitors, adhesives, and epoxy systems

- Research into low-carbon, alkali-activated cements as alternatives to traditional Portland cement

These contributions demonstrated the growing momentum behind environmentally responsible materials chemistry.

I had the opportunity to present my own research within the materials for energy and sustainability theme. My poster focused on the valorisation of end-of-life refractories as functional fillers, exploring the potential of two materials—mRefCem and mRefFerro. These materials, fully characterised in our materials passports, show promise as fillers in thermoset and thermoplastic systems, contributing to the circular economy.

Overall, MC17 was a thoroughly rewarding experience. The conference reinforced the importance of interdisciplinary collaboration and sustainable innovation in materials chemistry. I’m already looking forward to the next edition!

Authors’ Portrait

Jack Maxfield

Jack is a research scientist at the Centre for Process Innovation (CPI) working in the formulations team. He studied at the University of Sheffield and has a master’s degree in chemistry. His research interests are using materials science for sustainable applications.

Established in 1985, Norsk Elektro Optikk (NEO) is Norway’s largest independent research and development organization in the field of electro optics. Founded by scientists from the Norwegian Defence Research Establishment, NEO has grown into a globally recognized manufacturer of advanced electro-optical products. The company’s mission encompasses developing, manufacturing, and marketing electro-optical products based on in-house technology, as well as participating in research-oriented projects in collaboration with larger companies or research organizations where applications of electro-optical methods are essential.

NEO’s headquarters, laboratories, and production facilities are in a modern multi-purpose building in Bryn, near the center of Oslo. The company employs more than 60 people, over 70% of whom hold advanced degrees in physics or electronics. Their expertise spans electro-optical systems design, optical design, software development, mechanical design, diode laser technology, detector technology (IR and visual), spectroscopy, mathematical modeling, electronic design (hardware and software), and signal and image processing.

NEO’s product portfolio includes the HySpex line of hyperspectral imaging systems, which are renowned for their stability, flexibility, and superior data quality. These systems are utilized in various applications, including environmental monitoring, defense, and industrial inspection.

Role in the ReSoURCE Project

Within the ReSoURCE project, NEO contributes its expertise in hyperspectral imaging through its HySpex division. NEO’s primary responsibility involves delivering spatially and spectrally resolved data of materials on conveyor belts. This data serves as input for material classification and, in conjunction with 3D geometry sensor data, aids in the preselection of regions of interest (ROI) for controlling the LIBS (Laser-Induced Breakdown Spectroscopy) beam guiding system.

NEO’s involvement in the ReSoURCE project exemplifies its commitment to applying advanced electro-optical technologies to address industrial challenges, particularly in the realm of sustainable resource utilization and recycling.

For more information about NEO and its contributions to the ReSoURCE project, please visit their official website.

Climate change and its consequences are becoming more evident every day. If we want to shape a more sustainable and just future, we need smart minds who are not only aware of the challenges but also equipped to tackle them. That journey begins with our children and teenagers, who are already learning in school about climate-damaging behaviours and how to avoid them.

Supporting this mission, the European Union funds various initiatives focused on climate education. One of them is the Ecoality Project, which aims to empower young people with the skills and knowledge needed to address climate change and gender justice. As part of this initiative, Südwind Austria organized a School Climate Camp from June 13 to 17, bringing together 20 students for an inspiring and educational experience.

We at the Chair of Waste Processing Technology and Waste Management (AVAW) at Montanuniversität Leoben (MUL) were honoured to contribute to one full day of the program.

A Day with AVAW: From Understanding to Action

After a relaxed Sunday breakfast, the students were divided into four groups of five and introduced to the Climate Fresk – a collaborative workshop tool that visualises the causes and effects of climate change. The theme of the day was “From Head to Heart to Action”.

Through the Climate Fresk, the teenagers explored the science behind climate change and the consequences that await us if we fail to act. This was followed by a reflective session where students, in pairs, processed what they had learned and shared their emotional responses. The goal was to help them connect intellectually and emotionally with the topic – a vital step before taking meaningful action.

We then opened up a group discussion about what everybody of us can contribute to climate solutions. During this exchange, we also introduced our department at MUL and explained how future studies or careers in environmental and energy engineering can play a powerful role in fighting climate change.

Real Solutions in Action: ReSoURCE & MoLIBity

As part of our presentation, we showcased two of our key research projects:

- ReSoURCE

- MoLIBity, a project dedicated to developing efficient recycling processes for lithium-ion batteries from mobility applications. MoLIBity is led within our department by Fr. DI Cornelia Rutkowski.

Looking Ahead

We’re incredibly grateful to have been part of this fantastic Climate Camp experience. It was a real pleasure to engage with such thoughtful, curious, and motivated young people. The day was filled with insightful conversations, shared ideas, and moments of inspiration.

We look forward to possibly welcoming some of the participants to our university in the future – as students, researchers, or changemakers in the fight against climate change.

Authors’ Portrait

Florian Feucht

DI Florian Feucht is research associate at the Chair of Waste Management and Waste Treatment at the Montanuniversität Leoben and part of the Workgroup: “Environmental remediation and mineral waste”. Since 2023, he has been enrolled in the university’s PhD Program. He earned his master’s degree in Applied Geoscience from Montanuniversität Leoben, focusing on the chemical-mineralogical characterization of ladle slag. He completed his bachelor’s degree in Earth Sciences at the University of Vienna, with a thesis on the petrological study of mafic and ultramafic rocks. His research interests include the chemical mineralogical characterization of mineral wastes, mineralogy, slag mineralogy, recycling, and waste management.

Cornelia Rutkowski

DI Cornelia Rutkowski is research associate at the Chair of Waste Management and Waste Treatment at the Montanuniversität Leoben and part of the Workgroup: “Future Waste and Waste Management”. Since 2024, she has been enrolled in the university’s PhD Program. Her research is focusing on the development of a functional recycling process for Lithium-ion traction batteries from mobility applications. She earned her master’s degree in Applied Geoscience from Montanuniversität Leoben, focusing on the mineralogical differentiation of spodumene-bearing pegmatites and its host rocks as foundation for magnetic prospection. She completed her bachelor’s degree in Earth Sciences at the University of Vienna, with a thesis on the kinematic of the Periadriatic Fault System near Villach.

Every year, millions of tonnes of high-performance materials—refractories—are used in industries like steelmaking, cement production, and glass manufacturing. These materials withstand extreme heat and stress, lining furnaces, kilns, and reactors to keep industrial processes running. But what happens after they’ve done their job?

Too often, spent refractories end up in landfills or downcycling applications. That’s not only wasteful, it’s a missed opportunity. Many of these materials still have valuable properties and can be recycled, —if we can sort and process them effectively. That’s where new technology is stepping in.

Figure 1. Overview of manual recycling processing steps.

From Manual to Machine: A Recycling Revolution

Until recently, sorting used refractory bricks was a manual process. Workers can only handle large chunks (over 80 mm), and decisions are mainly based on visual inspection. It works, but is lacking in efficiency especially in a world where circularity and carbon reduction are urgent goals which need to be achieved quickly.

Now, a new generation of automated sensor-based sorting systems is up to make a big difference. These high-tech machines will handle much smaller particles (as small as 5 mm), sort them faster, and—most importantly—analyze their chemical composition in real time.

Using tools like Laser-Induced Breakdown Spectroscopy (LIBS) and Hyperspectral Imaging (HSI), these systems analyze each piece of material for its chemical and mineral content. That means recyclers can identify exactly what each particle is made of and separate it accordingly—resulting in higher-quality recycled materials.

A Game-Changer for Circularity

Why does this matter? Because better sorting means better recycling. When materials are accurately identified and separated, they can be reused in new refractory products without compromising performance. That reduces demand for virgin raw materials, saves energy, cuts carbon emissions, and keeps valuable resources in use.

RHI Magnesita, one of the world’s leading refractory producers, is pioneering this approach with support from the ReSoURCE project. Together with industry and research partners, the company is developing mobile sorting units—container-sized systems that can be deployed directly at customer sites. These units can process a couple of tonnes of used refractories per hour, making recycling more convenient, more economical, and more sustainable.

Building the Future, Brick by Brick

This kind of innovation is essential if we’re serious about creating a circular economy. By combining cutting-edge science with practical engineering, the refractory industry is rethinking waste—and finding new value in old materials.

At ReSoURCE, we believe that progress like this doesn’t just benefit industry —it benefits all of us. A smarter recycling system means a healthier planet, a more resilient supply chain, and a more responsible approach to the materials we depend on every day.

If you’re interested in the technical foundations behind this approach, you can read the full article published in RHI Magnesita’s Bulletin 2024 here.

Authors’ Portrait

Alexander Leitner

Alexander studied Material Science at the Montanuniveristät Leoben, focusing on the field of micromechanics and material physics. He joined RHI Magnesita’s Strategic Project and Innovation Team in 2019 and as of early 2025, serves as Head of Pioneer Research at RHI Magnesita.

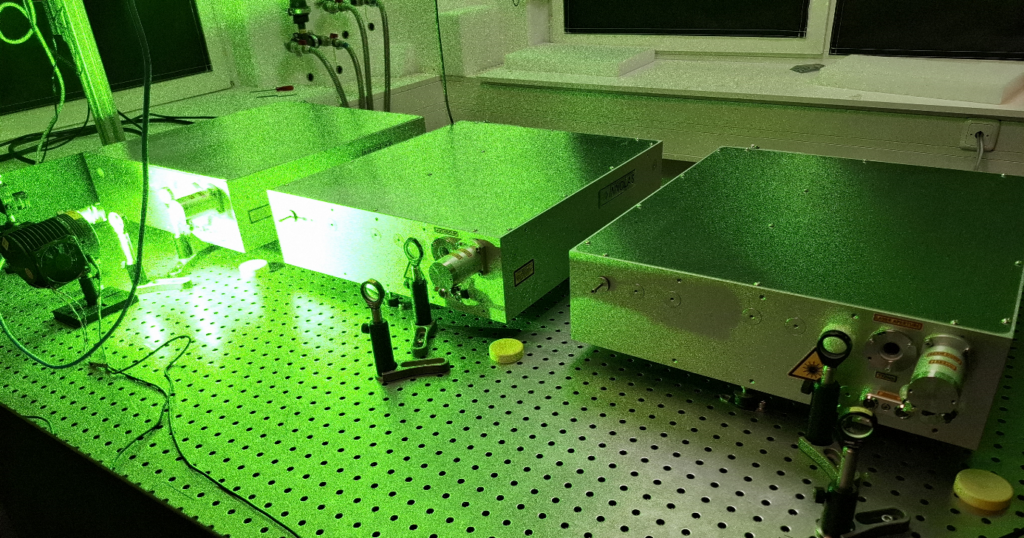

2025 marks the 30th anniversary of the foundation of InnoLas Laser GmbH. Since 1995, the development and manufacturing of highest quality laser sources for scientific and industrial applications made in Germany is the main drive of the company. Through the knowledge and teamwork of the employees, the laser systems produced are customized to the customer’s wishes. Within the first 20 years, the company grew and built laser systems for numerous different applications. For a better separation of the products, the company was split into several companies, each specializing in a different field. At InnoLas Laser, laser sources for scientific applications are the main focus.

InnoLas Laser produces flash lamp and diode pumped laser systems with pulse lengths in the upper picosecond and nanosecond range with pulse energies at 1064nm of a few µJ at 100 kHz to over 7J at 3 Hz and wavelengths of 1064nm to higher harmonic generations as well as OPO capabilities. The products manufactured cover a wide range of specifications needed for the even wider range of application possibilities such as Lidar, Ti-Sa pumping, Thomson scattering, photoacoustic … and in the case of the ReSoURCE project for the recycling of refractive materials.

Furthermore, the availability of technicians and the lifelong support of the laser systems allow the customers to maintain and if needed upgrade their laser systems over the years as specification changes appear in their applications.

InnoLas Laser, with the desire for development of new fields of application, participates in numerous projects in cooperation with international partners. In the case of the ReSoURCE project, to be able to obtain the desired LIBS analysis for sorting of the refractive material, specific changes in the emission output were needed. Through software, hardware and optical optimization the laser system was developed to reach the needed specification.

The headquarter of InnoLas Laser GmbH is located in Krailling near Munich, Germany. The in-house development of the components as well as a tight connection between all departments allows for a smooth planning and manufacturing of the laser systems according to the required specifications.

In 2022, InnoLas Laser GmbH opened another branch office and production facility in Windorf near Passau, Germany. The site was built according to the latest environmental standards and uses geothermal energy for heating and air conditioning. In addition, a high-performance photovoltaic system on the roof ensures a sustainable power supply for the building and the charging of company vehicles.

As founder Reinhard Kelnberger said: “For us a very pleasant working atmosphere is one very important pre-condition for such a well-coordinated and successful development. We are looking forward to more sustainable growth of our company, many new and old satisfied customers, new challenges and especially to improving our products for our costumer’s benefit!”

From 9–12 June 2025, the International Conference on Solid Waste 2025 (ICSWDG2025) has taken place. Hosted by Dongguan University of Technology, Zhejiang University, and the International Waste Working Group (IWWG), the gathering centered around “Waste Management for Carbon Neutrality and Circular Economy”.

The adoption of circular and green economy practices is essential for reducing environmental pollution and mitigating climate change. Despite this, the global economy remains only 7.2% circular, according to the 2024 Circularity Gap Report, highlighting a vast opportunity for progress. ICSWDG2025 offerd a vital platform for scientists, researchers, regional policymakers, and industry professionals to share insights on sustainable waste management, technology, and environmental challenges.

The ReSoURCE project was also presented at ICSWDG2025, contributing to the broader discussion on waste management. The presentation highlighted the project’s overarching objectives, emphasizing its focus on addressing a particularly significant and valuable waste stream within the broader context of sustainable resource management. Key findings from the analysis of the European waste management systems were shared. It concluded with the introduction of a GIS-based map, designed to improve data visualization and decision-making in waste management regarding spent refractories.

Personal notes: It was truly a wonderful and educational experience to participate in an international conference in China. A heartfelt thank you to Prof. Jonathan Wong for warmly welcoming the Austrian participants and taking such excellent care of us. Sincere thanks also to the organizing team for putting together such a well-organized event.

Authors’ Portrait

Florian Feucht

DI Florian Feucht is research associate at the Chair of Waste Management and Waste Treatment at the Montanuniversität Leoben and part of the Workgroup: “Environmental remediation and mineral waste”. Since 2023, he has been enrolled in the university’s PhD Program. He earned his master’s degree in Applied Geoscience from Montanuniversität Leoben, focusing on the chemical-mineralogical characterization of ladle slag. He completed his bachelor’s degree in Earth Sciences at the University of Vienna, with a thesis on the petrological study of mafic and ultramafic rocks. His research interests include the chemical mineralogical characterization of mineral wastes, mineralogy, slag mineralogy, recycling, and waste management.